Sintered Ferrite MAGNET

Home » Sintered Ferrite MAGNET

Sintered Ferrite

- Material: Sintered Ferrite Magnet, Permanent Magnetic Material

- Type: Permanent Magnetic Material, High Working Temperature Magnet

- Shape: Cylinder, Arc, Disc, Ring, Block, Customized

- Tolerance: ±0.1mm, Customized

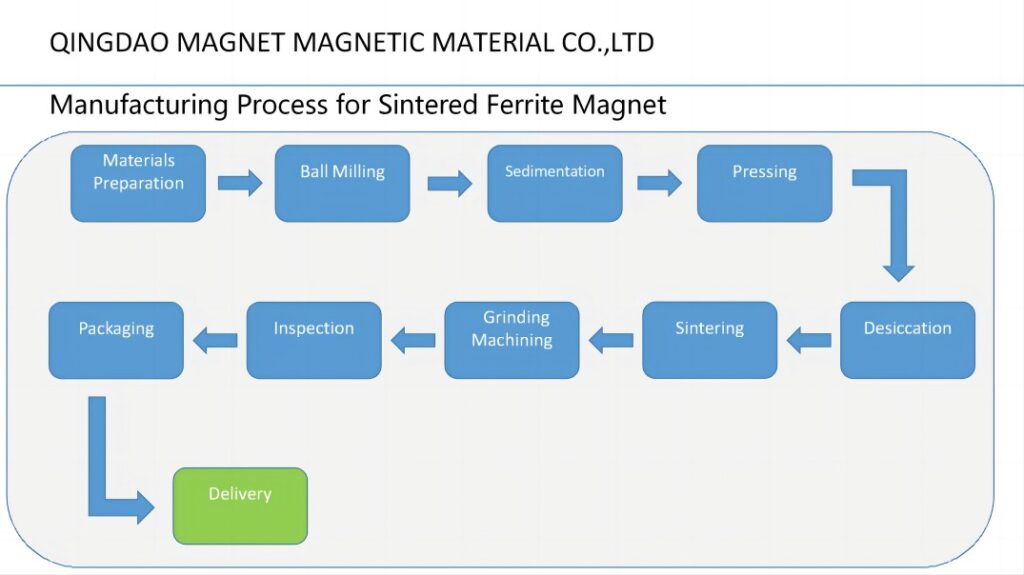

- Process: Mold, Cutting, Machining, Grinding

- Working Temperature: Max. 250℃

- Color: Black,Silver,Red,Customized

- Coating: NiCuNi, Al, Customized

Product introduction

A sintered ferrite magnet is one of the more common types of ferrite magnets we see in our lives. It has a black surface and stable magnetism, which is one of the major advantages of sintered ferrite magnets. Sintered ferrite magnets can operate at temperatures up to 250 degrees Celsius. Sintered ferrite magnets also have excellent corrosion resistance. Sintered ferrite magnets have been used in a wide range of applications over the last few decades, and even the range of applications for sintered neodymium magnets is still large .The market share of sintered ferrite magnets is becoming more and more widespread. Some of the most representative applications for sintered ferrite magnets include loudspeakers, permanent magnet (PM) motors and generators.

Physical Charateristics of Sintered Ferrite Magnet

Parameter | Mark | Unit | Value |

Recoil Permeability | μ Rec | Gs/Oe | 1.05-1.3 |

Curie Temperature | Tc | ℃ | 450 |

Temperature Coefficient of Remanence | α(Br) | ℃-1 | ’‘-0.2%(0-100℃) |

Temperature Coefficient of Magnetization Force | α(Hc) | ℃-1 | ’‘-0.2%-0.5% (0-100℃) |

Density | ρ | g/cm3 | 4.7-5.0 |

Resistivity | ρ | Ω*cm | ≥106 |

The Coefficient of Linear Expansion | α | ℃-1 | 7-15*10-6 |

Hardness | HV | – | 480-580 |

Performance Parameters

| Grade | Br | Hcb | HcJ | BH(Max) | |||||

| Gs | mT | Oe | kA/m | Oe | kA/m | MGOe | kJ/m³ | Comparable Grade | |

| MGT2130 | 2000-2350 | 200-235 | 1570-2009 | 125-160 | 2637-3516 | 210-280 | 0.81-1.19 | 6.5-9.5 | HF8/22、Y8T、C1、FB1A |

| MGT2330 | 2200-2400 | 220-240 | 1695-2198 | 135-175 | 3491-4019 | 278-320 | 1.06-1.39 | 8.5-11.1 | Y10T |

| MTG3337 | 3100-3600 | 310-360 | 2763-3140 | 220-250 | 3516-4019 | 280-320 | 2.5-3.5 | 20-24 | HF20/28、Y22H |

| MTG3631 | 3500-3800 | 350-380 | 2826-3140 | 225-250 | 2951-3265 | 235-260 | 3.1-3.7 | 24.7-29.5 | HF25/22、Y26H-1 |

| MGT3640 | 3500-3700 | 350-370 | 3100-3500 | 247-279 | 3800-4300 | 303-342 | 2.8-3.4 | 22.3-27.1 | C7、PMF-2BB |

| MGT3730 | 3600-3900 | 360-390 | 2512-3140 | 200-250 | 2836-3202 | 225-255 | 2.9-3.5 | 23.1-27.9 | HF22/30、Y27H |

| MGT3742 | 3600-3800 | 360-380 | 3303-3617 | 241-288 | 3994-4396 | 318-350 | 3.0-3.5 | 23.9-27.9 | HF24/35、Y26H-2 |

| MGT3749 | 3600-3800 | 360-380 | 3391-3705 | 270-295 | 4797-5086 | 382-405 | 3.3-3.8 | 26.3-30.3 | Y28H-2 |

| MGT3820 | 3600-4000 | 360-400 | 1695-2135 | 135-170 | 1758-2512 | 140-200 | 2.8-3.5 | 22.3-27.9 | HF25/14、Y25 |

| MGT3825 | 3700-4000 | 370-400 | 2198-2637 | 175-210 | 2260-2763 | 180-220 | 2.9-3.8 | 23.1-30.3 | HF26/18、Y28 |

| MGT3828 | 3700-4000 | 370-400 | 2300-2700 | 183-215 | 2500-3000 | 199-239 | 2.9-3.8 | 23.1-30.3 | C5 |

| MGT3838 | 3700-4000 | 370-400 | 3200-3600 | 255-287 | 3700-4100 | 263-326 | 3.0-3.7 | 23.9-29.5 | C9 |

| MGT3849 | 3700-3900 | 370-390 | 3100-3500 | 246-279 | 4800-5200 | 382-415 | 3.1-3.7 | 24.7-29.5 | Y28H-2、FB6E、PMF-28F |

| MGT3926 | 3800-4000 | 380-400 | 2300-2700 | 183-215 | 2400-2800 | 191-223 | 3.4-4.0 | 27.1-31.8 | Y30 |

| MGT3930 | 3800-4050 | 380-405 | 2800-3200 | 223-255 | 2900-3300 | 230-263 | 3.4-4.0 | 27.1-31.8 | HF26/26、Y30H-1、Y30BH |

| MGT3934 | 3800-4000 | 380-400 | 3000-3400 | 238-270 | 3200-3600 | 255-287 | 3.5-4.0 | 27.8-31.8 | C8、PMF-2BD |

| MGT3939 | 3800-4000 | 380-400 | 3200-3600 | 255-287 | 3800-4200 | 303-334 | 3.2-4.0 | 25.5-31.8 | HF26/30、PMF-2BE |

| MGT4026 | 3900-4000 | 390-400 | 2300-2700 | 183-215 | 2400-2800 | 191-223 | 3.3-4.0 | 26.3-31.8 | HF32/17 |

| MGT4030 | 3900-4100 | 390-410 | 2800-3200 | 223-255 | 2900-3300 | 230-263 | 3.5-4.1 | 27.8-32.6 | FB3N、C8A |

| MGT4034 | 3900-4100 | 390-410 | 3000-3400 | 238-270 | 3200-3600 | 255-287 | 3.5-4.2 | 27.8-33.4 | FB4B、C10 |

| MGT4038 | 3900-4100 | 390-410 | 3200-3600 | 255-287 | 3600-4000 | 287-318 | 3.6-4.2 | 28.7-33.2 | |

| MGT4040 | 3900-4150 | 390-415 | 3300-3700 | 263-295 | 3800-4200 | 303-334 | 3.6-4.3 | 28.7-34.2 | FB5H、Y30H-2、C12、 PMF-5BE |

| MGT4045 | 3900-4100 | 390-410 | 3300-3700 | 263-295 | 4350-4800 | 346-382 | 3.6-4.3 | 28.7-34.2 | FB6B、PMF-6BE |

| MGT4050 | 3900-4100 | 390-410 | 3400-3800 | 270-303 | 4800-5200 | 382-415 | 3.5-4.2 | 27.8-33.4 | PMF-6BE |

| MGT4123 | 4000-4200 | 400-420 | 2000-2400 | 159-191 | 2100-2500 | 167-199 | 3.6-4.2 | 28.7-33.4 | |

| MGT4126 | 4000-4200 | 400-420 | 2300-2700 | 183-215 | 2500-2900 | 199-231 | 3.6-4.3 | 28.7-34.2 | |

| MGT4129 | 4000-4200 | 400-420 | 2700-3100 | 215-247 | 2800-3200 | 223-255 | 3.7-4.3 | 29.5-34.2 | |

| MGT4132 | 4000-4200 | 400-4200 | 2900-3300 | 230-263 | 3000-3400 | 238-270 | 3.7-4.3 | 29.5-34.2 | |

| MGT4135 | 4000-4200 | 400-420 | 3100-3500 | 246-279 | 3300-3700 | 263-295 | 3.8-4.4 | 30.3-35 | FB5B、PMF-5BD、Y33H |

| MGT4138 | 4000-4200 | 400-420 | 3300-3700 | 263-295 | 3600-4000 | 287-318 | 3.8-4.4 | 30.3-35 | |

| MGT4141 | 4000-4200 | 400-420 | 3400-3800 | 270-303 | 3900-4300 | 310-342 | 3.8-4.5 | 30.3-35.8 | |

| MGT4150 | 4000-4200 | 400-420 | 3400-3800 | 270-303 | 4800-5200 | 382-415 | 3.8-4.5 | 30.3-35.8 | |

| MGT4228 | 4100-4300 | 410-430 | 2400-2800 | 191-223 | 2600-3000 | 207-239 | 3.8-4.5 | 30.3-35.8 | |

| MGT4230 | 4100-4300 | 410-430 | 2600-3000 | 207-239 | 2800-3200 | 223-255 | 3.8-4.5 | 30.3-35.8 | |

| MGT4234 | 4100-4300 | 410-430 | 3000-3400 | 239-270 | 3200-3600 | 255-287 | 3.9-4.5 | 31-35.8 | FB4X、 PMF-6BB、C11、Y33 |

| MGT4237 | 4100-4300 | 410-430 | 3200-3600 | 255-287 | 3500-3900 | 279-310 | 3.9-4.6 | 31-36.6 | |

| MGT4240 | 4100-4300 | 410-430 | 3500-3900 | 279-310 | 3800-4200 | 303-334 | 4.0-4.6 | 31.8-36.6 | PMF-7BE |

| MGT4245 | 4100-4300 | 410-430 | 3500-3900 | 279-310 | 4350-4800 | 346-382 | 4.0-4.6 | 31.8-36.6 | |

| MGT4254 | 4100-4300 | 410-430 | 3600-4000 | 287-318 | 5100-5500 | 406-438 | 4.0-4.6 | 31.8-36.6 | PMF-9BG |

| MGT4328 | 4200-4400 | 420-440 | 2500-2900 | 199-231 | 2600-3000 | 207-239 | 4.0-4.6 | 31.8-36.6 | |

| MGT4335 | 4200-4400 | 420-440 | 3200-3600 | 255-287 | 3400-3800 | 270-303 | 4.1-4.5 | 32.6-35.8 | FB6N、PMF-7BD、 Y36 |

| MGT4350 | 4200-4400 | 420-440 | 3600-4100 | 287-326 | 4800-5200 | 382-415 | 4.1-4.7 | 32.6-37.4 | FB9H、PMF-9BF |

| MGT4429 | 4300-4500 | 430-450 | 2700-3100 | 215-247 | 2800-3200 | 223-255 | 4.1-4.8 | 32.6-38.2 | PMF-7BB |

| MGT4435 | 4300-4500 | 430-450 | 3000-3400 | 239-270 | 3300-3700 | 263-295 | 4.1-4.8 | 32.6-38.2 | |

| MGT4445 | 4300-4500 | 430-450 | 3700-4100 | 295-326 | 4300-4700 | 342-375 | 4.2-4.8 | 33.4-38.2 | FB9B、PMF-9BE、Y40 |

| MGT4450 | 4300-4500 | 430-450 | 3700-4200 | 295-334 | 4800-5200 | 382-415 | 4.1-4.8 | 32.6-38.2 | PMF-12BG |

| MGT4537 | 4400-4600 | 440-460 | 3100-3600 | 246-287 | 3500-4000 | 279-318 | 4.2-5.0 | 33.4-39.8 | FB9N、PMF-9BD、 Y38 |

| MGT4647 | 4500-4700 | 450-470 | 3600-4200 | 287-334 | 4500-4900 | 358-390 | 4.3-5.2 | 34.2-41.4 | PMF-12BF |

Advantages of Sintered Ferrite Magnet

- Excellent rusty proof

- Stable magnetic performance

- High working temperature

- Processed by mold, press to shape ensure high efficient and good stability of products

- Relative economical cost

Sintered Ferrite Magnets with shapes of block, arc segment,cylinder and diametrically or radially multipole ring, widely used in pump motors, loudspeakers, cow magnets, sensors, etc.

Related products